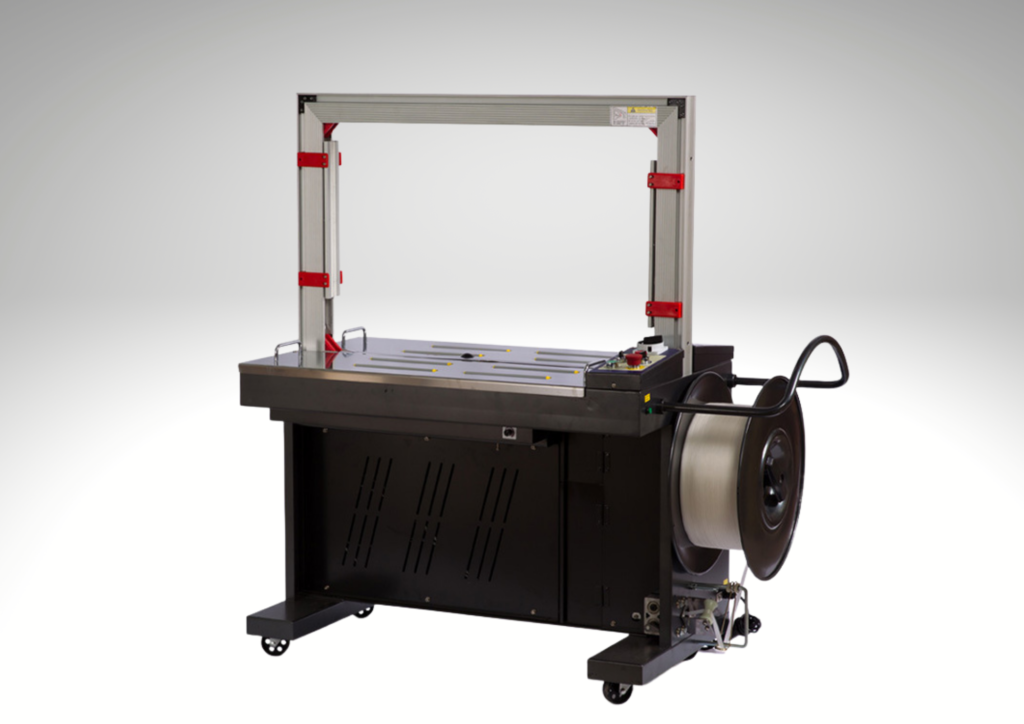

FULLY AUTOMATIC STRIP PACKING MACHINE

An automatic box strapping machine is a packaging equipment designed to automate the process of strapping or banding boxes, packages, cartons, or bundles using plastic strapping material. Here’s an overview of its features and operation

Fully Automated Operation

An automatic box strapping machine is capable of performing the entire strapping process without the need for manual intervention. It typically features sensors, motors, and controls that automate the feeding, tensioning, sealing, and cutting of the strapping material.

Strap Feeding

The machine automatically feeds the strap around the package as it enters the strapping station. Sensors detect the presence of the package and activate the strap feeding mechanism accordingly

Tensioning

Once the strap is fed around the package, the machine automatically applies the desired tension to ensure the strap is securely tightened. Tensioning mechanisms may include pneumatic tensioners or motor-driven tensioning systems.

Sealing

After the desired tension is applied, the machine seals the strap using heat seal, friction weld, or other sealing methods, depending on the machine’s design. The sealed joint ensures that the strap remains securely attached to the package.

Cutting

After tensioning, the machine automatically seals the strap using heat seal, friction weld, or other sealing methods. The sealing process creates a strong and secure joint that holds the strap in place around the package.

Continuous Operation

Automatic box strapping machines are capable of continuous operation, allowing for high-speed strapping of multiple packages in succession. They are well-suited for high-volume packaging environments where efficiency and productivity are paramount.

Adjustability and Flexibility

Many automatic strapping machines offer adjustable settings for tension, sealing temperature, and other parameters to accommodate different package sizes and strapping requirements. Some machines may also feature programmable controls for storing and recalling specific strapping configurations.

Reliability and Efficiency

Automatic machines offer consistent and reliable performance, minimizing human error and ensuring uniform strapping quality.They significantly improve packaging efficiency and throughput compared to manual or semi-automatic strapping methods.

Overall, automatic box strapping machines are essential equipment in industries with high packaging volumes, such as manufacturing, logistics, distribution centers, and warehouses. They offer efficient, reliable, and hands-free strapping solutions for securing packages during transit and storage.